Each airline operator must still work independently with the airport and agree to an operational plan. By granting approval, the airports on this list have indicated that the 747-8 can operate safely in their airport environment. Airports that may have deficient pavement strength are working directly with Boeing's engineering staff for resolution. The airlines, with Boeing technical assistance as required, are conducting parking discussions with the airports.

Current Status List of 747-8 Airports, mapof airports which have supported revenue service, and Mapsof Destination and Alternate Airports that have granted Approval to Operate a 747-8 - Final airport compatibility resolution can only be achieved once regulatory, pavement loading and parking issues are all resolved. Arie 747 cambam cnc code#

For any areas of non-compliance, a proposed set of minimum separations and, if required, operational procedures proposed by the BACG to ensure the safe operation of the 747-8 aircraft at aerodromes currently unable to meet ICAO Code Letter F aerodrome Standards and Recommendations. ICAO Recommended Practices relating to those items, and. Items of aerodrome infrastructure that may be affected by the introduction of the Boeing 747-8 aircraft. The purpose of BACG Common Agreement Document is to develop 747-8 operational guidance material based on ICAO Circular 305, that includes: It is formed to agree and promote a common position among the group members, with respect to operation of the 747-8 at existing airports that currently do not meet ICAO Code Letter F specifications. Airport Council International (ACI) Boeing 747-8 Airport Compatibility Group (BACG) Document- The BACG Chartered by ACI-World is a group consisting of Civil Aviation Authorities, Airports, and Industry representatives. kuk gay milfaholico analskdande pop cam bam del det ) sitt studenter. US Airports - Approved FAA Modification of Standards (MOS) for 747-8. North America / Central America/ Caribbean. Note that EB80 and EB81 have been incorporated into the latest version of AC 150/5300-13A, Airport Design. EB73 - Use of Non-Standard 75-foot (23-M) Wide Straight Taxiway Sections for Boeing 747-8 Taxiing Operations. EB74A - Use of 150-foot (45-M) Wide Runways and Blast Pads for Boeing 747-8 Operations. FAA Type Certificate Data Sheet (Revision 58). Operating the 747-8 at Existing Airports (AERO Magazine). Since most of the world's major airports are built to ICAO Code E standards, Boeing is working, on behalf of our airline customers, with airports and Civil Aviation Authorities worldwide to ensure that the proper plans are in place to accommodate safe and economical operations. after a quick rub with a fine oilstone i put it in my ultrasound cleaner to get rid of grease, dirt and chips.While the 747-8 retains many of the same exterior dimension as the 747-400 (tail height, engine span, main landing gear post span), the increased wingspan of the 747-8 aircraft places it into ICAO airport design category F. i snapped the point on a previous job, some 0.08mm of the tip is missing, making it 0.2 mm at the tip.)įinished milling. (can you believe i actually used a blunt V-cutter?. It just looks so crisp, and the text is only 3 mm high.

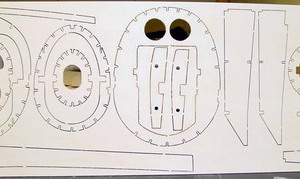

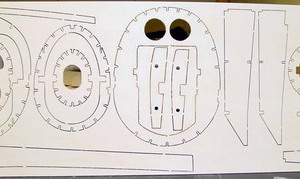

These look like grooves, but there's also a cavity for the "lock"of a cable-tie, and tool 2 is loaded, a 3mm (0.118") endmillĪfter that one, it was on to tool 3, a v-cutter for mirrored text engraving, i took the tip of Doanwannapickle for the engraving, i sort of had to, because the text wasn't a text anymore, but just polylines Our somewhat messy shed, with the beagle-1 prepared for Take offĪligning the Quadrails before clamping the stock aluminium This is a BIG thankyou for all CamBam Users, helping me out with the problems i encounterd when making this mold.ĭesigning and programming of the cavities itself was, of course, no problem at all, but mirroring my firmname was "quite a different cattle of fish" to say the least. the source DXF files will be given to "the old man". So here we have a set of sample gaskets to fit onto the cilinders of the racers.Īs always i used CamBam to program the MOps and generate the code. So before he'd waste precious budget on waterjet-cut gaskets, i thought, i might as well cut some sample gaskets on the Beagle-1, to see if they do fit. so he asked me if it was possible to measure-up a set of gaskets and "digitize" the data to have gaskets cut with a waterjet. Since the height of a cilinder and the thickness of gaskets can be used to modify and adjust squish-height and compression ratio, he wanted gaskets of different thicknesses. My girlfriends father is a well known tuner and the ducati's he tunes are driven by his son ( my brother in law so to speak. This morning i fired up CamBam to machine some sample gaskets for a Ducati 1098 motorcycle.

It has been a while since i bored you with my seemingly endless stream of information.

0 kommentar(er)

0 kommentar(er)